In 1938, Dr. Plunkett of Du Pont company in the United States discovered an insoluble, non-melting waxy white powder formed by gas phase polymerization of tetrafluoron , which was determined by analysis to be Polytetrafluoroethylene (PTFE), and large-scale industrial production of the material began in 1950. PTFE has excellent chemical corrosion resistance, excellent heat resistance and low friction coefficient, self-lubrication, flame retardant, waterproof and other properties, has been widely used in petrochemical, electronic and electrical, aerospace, semiconductor, textile, biomedicine and other industrial fields.

With the continuous expansion of PTFE market demand, a single PTFE physical, chemical and processing properties have been unable to meet the market demand, especially PTFE does not resist creep, melt viscosity is high difficult to process molding, poor thermal conductivity, poor material adhesion and other performance defects seriously restrict the development prospects of PTFE. Therefore, PTFE application market could be greatly expand by modifying PTFE filler, blending and other methods to improve the performance.

The modified PTFE fine resin was extruded and sintered to obtain PTFE pipe, and then the phase change condensed dust removal and waste heat recovery and utilization device was prepared by welding. Compared with metal or PFA materials, the product has the advantages of light weight, long life and low price.

PTFE EXTRUSION PIPE

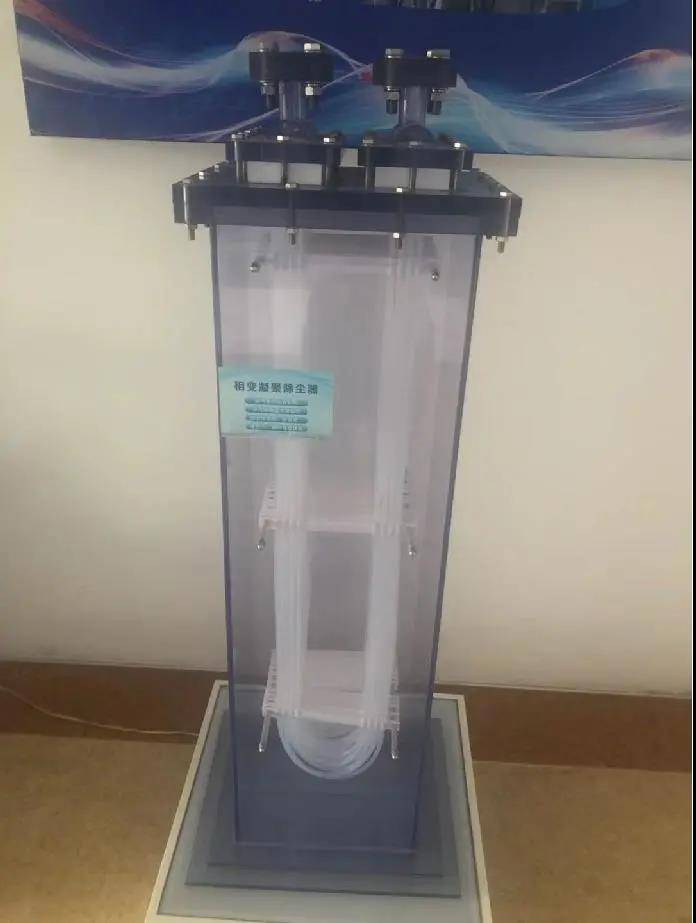

Model of phase change condensed precipitator

Real substance of phase change condensed precipitator

In recent years, Juhua takes advantage of more than 20 years of focus on the development and production of new fluorine materials. It has organized thermal Power Company, Feida Environmental Protection, fluoropolymer Business Department and other enterprises to carry out collaborative research and development, and cooperated with colleges and universities to carry out technical cooperation. After years of independent research and development and application tests, It has successfully developed the related technologies of phase change condensing dust removal and waste heat recovery and utilization device and low temperature coal economizer for coal power unit prepared by using new fluorine plastics, fill the blank of coal power plant energy conservation and emission reduction and whitening advanced technology.

At present, the technology has been successfully applied in the engineering of Juhua thermoelectric unit. So far, it has been running stably with remarkable effects of energy saving, water saving, dust removal and bleaching, and has obtained good economic and environmental benefits.