Broadly speaking, all fluorine containing rubber can be called fluorine rubber, usually there are the following four types:

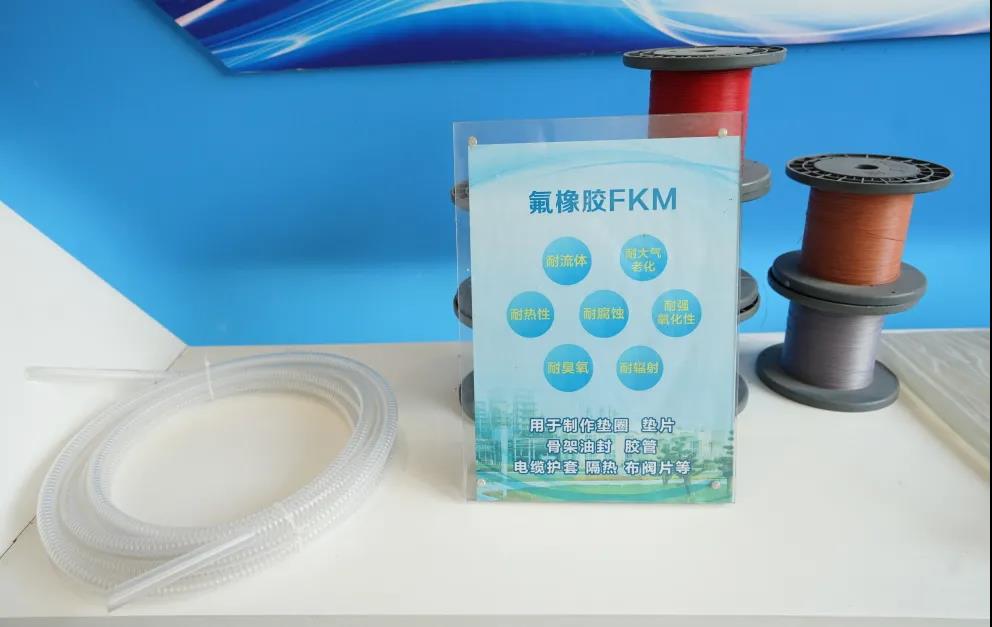

Vinylidene fluoroethylene fluororubber (FKM)

Most of the fluorine rubber to vinylidene fluoride as the main component, integrated heat resistance, drug resistance, solvent resistance, mechanical properties of fluorine rubber in the automotive use as the center of chemical, machinery and other industries have been widely used, mainly 26 and 246 fluorine rubber.

Tetrafluoro rubber (FEPM)

It is made of tetrafluoron (TFE) and propylene (Pr) by equal reaction. It has excellent durability and electrical properties (volume inherent resistance), such as resistance to strong acid, alkali and water vapor. Widely used in chemical industry, food industry sealing material or wire coating material. The third component vinylidene fluoride (VDF) was added to improve oil resistance and cold resistance.

Perfluorinated rubber (FFKM)

Excellent heat resistance, drug resistance, solvent resistance, almost all drugs and solvents. This feature can be used in semiconductor, oil mining and aerospace industries. The only disadvantage is that the price is too high. The market price is about RMB 30,000 to 50,000 yuan /kg.

Other fluorine rubber

This kind of rubber has good cold resistance and solvent resistance, but it is poor in heat resistance compared with silica gel without fluorine. In practical application, the problem of poor heat resistance is improved by adding various stabilizers, and the price is about 500-700 yuan /kg.

Because of its excellent high temperature resistance and oil resistance, fluorine rubber is widely used in the automotive field, with an application proportion of about 60-70%. Its typical applications are as follows:

1. fuel pump seal: the fuel pump is installed inside the fuel tank, directly in contact with gasoline. Therefore, the sealing ring is required to have good gasoline resistance.

2. refueling cover sealing: due to the strict provisions of gasoline evaporation, low fuel permeability requirements are higher.

3.oil level gauge, ventilation valve seal: the seals around the fuel tank have been in contact with gasoline, so it requires good gasoline resistance. The function of the ventilation valve is to discharge the gas inside the fuel tank and reduce the air pressure inside the fuel tank. The sealing of these two parts will also use fluorine rubber.

4.oxygen sensor seal: the role of the oxygen sensor is to detect the oxygen concentration in the exhaust gas and measure the air fuel ratio in the engine, and the data information feedback to the computer. Oxygen sensors are installed in the engine's exhaust pipe and come in direct contact with high-temperature exhaust gases. Therefore, oxygen sensor seals require good heat resistance.

5. fuel injector O ring: the role of the fuel injector is to spray a fog of gasoline and make gasoline and air mix. The mixture is fed into the cylinder and burned. The fuel injectors are installed around the combustion chamber of the engine and come into contact with the gasoline at high temperatures. Therefore, the O-ring requires good heat resistance and gasoline resistance.

6.crankshaft oil seal: crankshaft oil seal is one of the engine parts, in high temperature and oil contact. Therefore, it is necessary to use materials with excellent heat resistance and oil resistance.

7. Valve oil seal: the valve oil seal is used to prevent engine oil from entering the combustion chamber. The valve oil seal is one of the parts of the engine that comes into contact with gasoline and oil at high temperatures. Therefore, it is necessary to use materials with excellent heat resistance and oil resistance.

8.turbocharger tube: the role of the turbocharger tube is to compress the high temperature air in the turbocharger into the intercooler. With the improvement of the heat resistance of the supercharger system, the intake pipe material of the intercooler is changed from silicon rubber to fluorine rubber with better heat resistance.

At present, the type 26 and 246 fluororubber and peroxidation fluororubber developed and produced by Juhua have been widely used in automobile, new energy, chemical industry, machinery, aerospace and other fields, and have won consistent praise in the market.